In order to stay in business a manufacturing company must be both productive and efficient. In fact manufacturing companies must maintain as many efficient processes as possible. Industrial robots integrated into manufacturing processes can provide an effective way for manufacturing companies to increase their efficiency and quality while decreasing their waste.

Implementing certain manufacturing methods involves reducing unnecessary steps, movements and other waste. In manufacturing terms, waste occurs whenever tasks take place that are not considered value-added tasks. A value-added task adds to or manipulates a product in such a way that it increases its value in the eyes of the consumer. One example of a task that is not a value-added task would be walking to and from a toolbox to collect the necessary tools. Eliminating these types of tasks from the manufacturing process can make a manufacturing company much more efficient and successful.

Even though an industrial robot could cause overproduction of products when running at full capacity, manufacturing companies will not typically run their industrial robots at full capacity unless consumer demand requires it. By running industrial robots and production lines at speeds equal to consumer demand manufacturing companies can be much more flexible with the products they produce. This avoids additional costs related to counting, transporting and storage of overproduced products. Industrial robots can provide manufacturers with many quality and safety benefits.

If a manufacturing company needs to change a certain manufacturing process the last thing they want is for industrial robots getting in the way of completing their orders. This is why several smaller industrial robots are used to perform several different tasks instead of one robot used to perform multiple tasks. This allows for much greater flexibility.

Industrial robots can dramatically increase a manufacturing company’s product quality and reduce the incidence of injury. Industrial robots are able to perform manufacturing applications with perfect accuracy and create a variety of products with superior quality. Additionally, workers are able to work in much safer environments while industrial robots handle the dangerous ones since chemicals, tight spaces and hazardous environments do not pose any threat to robots.

Bay Industrial Group specializes in solving complex manufacturing problems. The expert automation designers, project managers, fabricators and welders at Bay Industrial Group are highly trained and experienced to work with a wide variety of industries in order to locate and create solutions to problems in their manufacturing processes. For more information please contact Bay Industrial Group today.

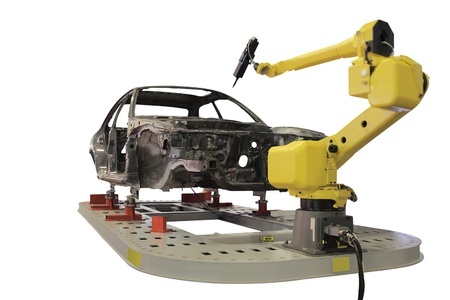

An industrial robot is an automatically controlled, reprogrammable, multipurpose manipulator that is programmable in three or more axes. Today, industrial robots are used for a variety of different manufacturing applications including:

An industrial robot is an automatically controlled, reprogrammable, multipurpose manipulator that is programmable in three or more axes. Today, industrial robots are used for a variety of different manufacturing applications including: